Digital printing has transformed the world of custom t-shirts. Whether you’re a designer, entrepreneur, or simply a fan of personalized apparel, this technique offers unmatched precision, vibrant colors, and endless creative possibilities.

In this complete guide, we’ll dive deep into everything you need to know about digital printing on t-shirts—from how it works to its benefits, best fabrics, and more.

What Is Digital Printing on T-Shirts?

Digital printing—often referred to as Direct-to-Garment (DTG) printing—is a cutting-edge method where ink is sprayed directly onto the fabric using advanced inkjet technology. Think of it like a high-end printer designed specifically for textiles.

Unlike traditional screen printing, which uses stencils and layers of ink, digital printing applies water-based inks straight to the fibers. The result? Ultra-soft prints that feel as natural as the fabric itself.

Why Digital Printing Is Revolutionizing Custom T-Shirts

Superior Print Quality

Digital printing delivers incredible clarity and detail, making it perfect for complex designs, gradients, and even photographs. The colors stay rich and true to the original artwork.

Cost-Effective for Small Batches

Unlike screen printing, which requires expensive setup for each color, digital printing involves minimal setup. Whether you need 1 shirt or 100, the cost remains reasonable—ideal for startups, artists, and limited-edition drops.

Unlimited Color Options

From bright neon shades to soft pastels, digital printing lets you use as many colors as you want—without additional costs.

Fast Turnaround Times

Once your design is ready, printing begins immediately. No need for lengthy prep work, which makes this process perfect for last-minute orders.

Eco-Friendly Process

Digital printing is one of the most sustainable t-shirt printing methods, thanks to water-based inks and minimal waste.

How Digital Printing Compares to Other Techniques

| Feature | Digital Printing (DTG) | Screen Printing | Heat Transfer Vinyl (HTV) | Sublimation |

|---|---|---|---|---|

| Setup Time | Minimal | High (screens per color) | Medium | Medium |

| Best For | Detailed designs, photos | Large orders with simple designs | Simple graphics, text | Polyester fabrics |

| Color Options | Unlimited | Limited (per-color cost) | Limited | Vivid but limited to polyester |

| Feel on Fabric | Soft, fabric-like | Slightly raised | Layered feel | Dye becomes part of fabric |

| Durability | High (when properly cared for) | Very high | Moderate (may peel) | Extremely durable |

Best Fabrics for Digital Printing

Digital printing performs best on natural fabrics or blends with high cotton content:

- Cotton & Cotton Blends: Excellent ink absorption, soft feel, and long-lasting color.

- Tri-Blend (Cotton, Polyester & Rayon): A great mix of comfort, durability, and printability.

- Bamboo & Organic Cotton: Sustainable options that print beautifully.

- Linen Blends: Unique texture with good print results (though very textured linen may affect clarity).

Avoid:

- High-polyester fabrics (over 40% polyester)

- Heavily textured or chemically treated fabrics

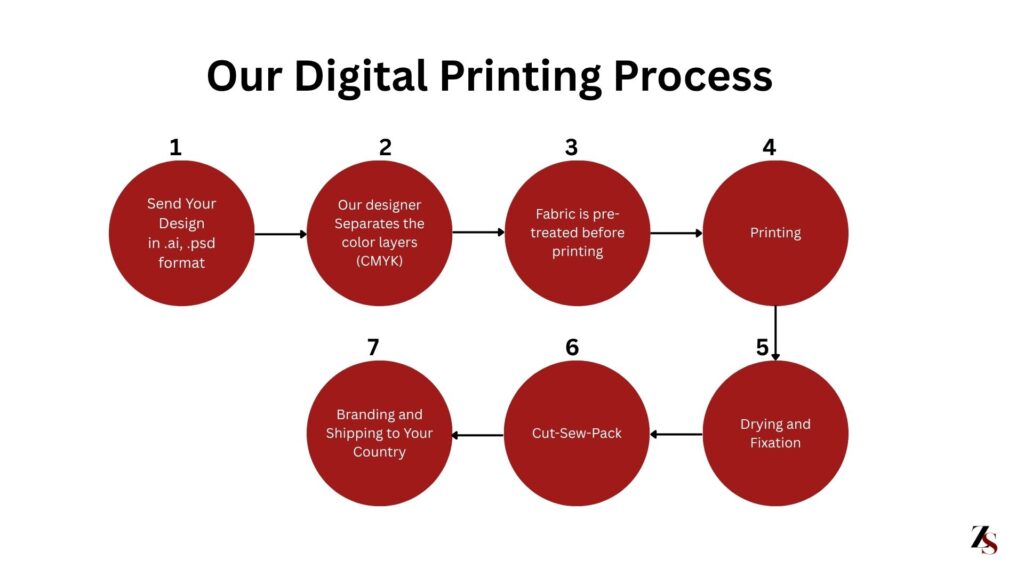

Step-by-Step: The Digital Printing Process

- Design Preparation:

Create high-resolution artwork (300 DPI) in CMYK color mode for best results. - Garment Pretreatment:

A pretreatment solution helps inks bond with fabric fibers, followed by partial heat curing. - Printing:

The shirt is loaded onto the printer, and precise ink droplets create the design with rich color layers. - Curing:

The printed shirt is cured with heat to lock in the colors and ensure wash durability.

Key Factors for High-Quality Prints

- Premium Inks: Better color vibrancy and longer-lasting prints.

- High Resolution: Opt for 1200 DPI or higher for sharp details.

- Color Management: Use proper color profiles to ensure accurate results.

- Fabric Prep: Pre-washed fabrics improve ink absorption and prevent shrinkage.

Care Tips for Digital Printed T-Shirts

- Wash inside out with mild detergent in cold water.

- Avoid bleach, fabric softeners, and high heat drying.

- Store in cool, dry places away from sunlight to prevent fading.

Popular Applications of Digital Printing

- Custom Apparel Brands: Perfect for small-batch production and custom designs.

- Print-on-Demand Stores: Enables zero-inventory business models.

- Promotional Wear: Quick production for events, teams, and marketing campaigns.

- Art & Fashion: Lets designers create wearable art without mass production.

Conclusion

Digital printing on t-shirts has unlocked an entirely new era of creative freedom and customization in the apparel world. With its unmatched detail, rapid production, and eco-conscious approach, it’s the go-to method for businesses, artists, and anyone who loves personalized fashion.

As technology continues to evolve, digital printing will only get faster, greener, and more accessible—empowering even more people to create stunning, custom t-shirts with ease.

Ready to start your digital printing journey?

Whether you’re launching a clothing line or creating custom merchandise, digital printing offers the perfect blend of quality, flexibility, and speed. Contact us today for your brand.